FINE QC™ Loudspeaker and Audio QC System

End of Line Loudspeaker and Audio QC Test System

Highly Accurate, Fast and Easy to Use

Buy FINE QC Loudspeaker and Audio QC System today!

Engineered specifically for modern audio manufacturing environments, the FINE QC Loudspeaker and Audio QC System delivers fast, reliable, and automated quality control for loudspeakers, headphones, micro speakers, microphones, amplifiers, and crossovers. Designed by industry experts with decades of experience, it replaces slow, inconsistent manual testing with high-precision automated analysis.

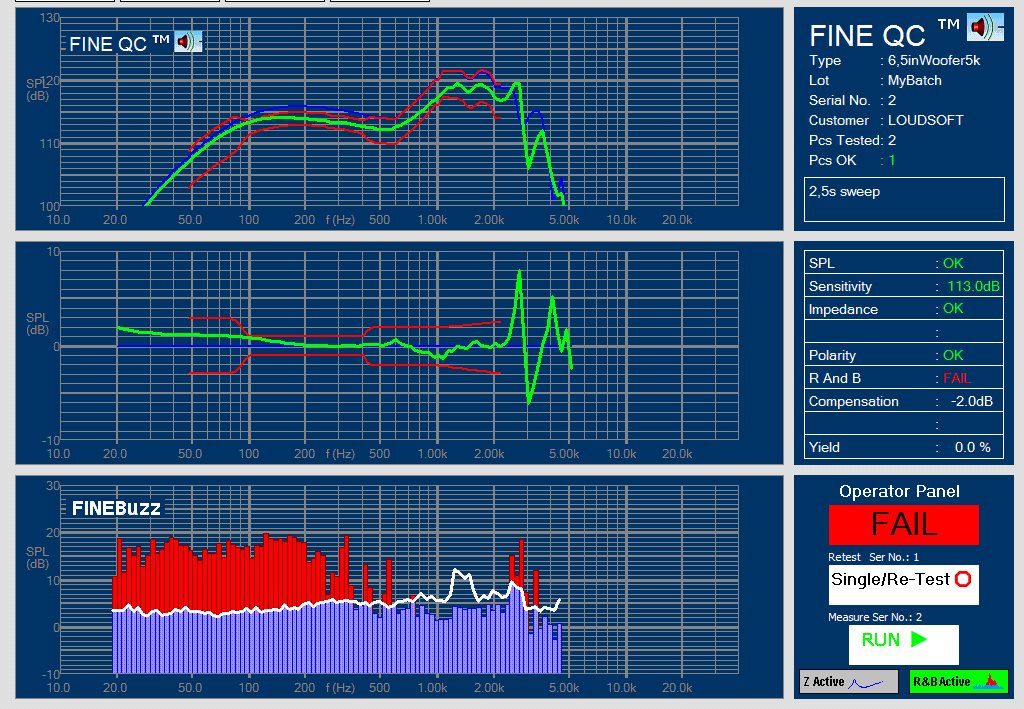

The system includes the advanced, self-learning FINEBuzz Rub & Buzz detection algorithm, the Best in the Industry– in just 0.5 to 1 second. Proven by customers to be the most effective alternative to human testing, FINE QC enables clear visual feedback—what our customers describe as: “See what You Hear with FINE QC.”

Key features include:

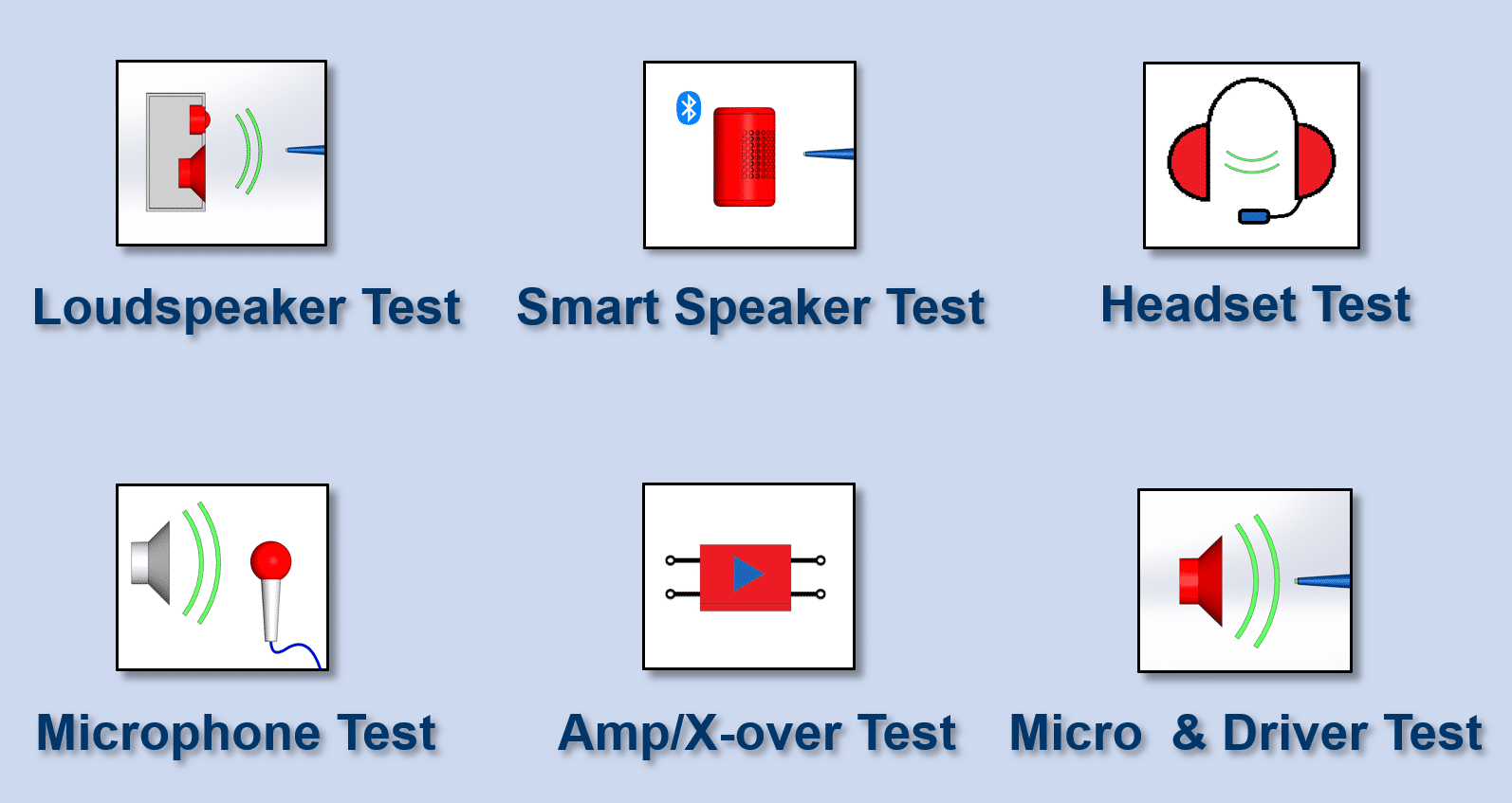

Support for all audio components: Easily test smart speakers, drivers, headphones, microspeakers, microphones, crossovers, and amplifiers.

Rub & Buzz detection with FINEBuzz: Adaptive algorithm learns from production samples and improves over time.

Automated Golden Average Matching: Automatically identify reference speakers and perform acoustic pair matching.

Comprehensive data management: All test measurements are automatically saved for traceability, statistics, and continuous improvement.

Integrated hardware: USB-controlled hardware includes phantom-powered microphones, AD/DA conversion, and built-in power amplifier for simultaneous SPL and impedance testing—no switching required.

Advanced automation support:

Seamlessly integrates with automatic or semi-automatic production lines

TTL Automation I/O Interface for control signal exchange

Real-time PASS/FAIL output for reject sorting and QC feedback

Optional second USB interface enables granular reject type categorization for smart assembly line management

Trusted by leading global audio brands including Bravox, JL Audio (Garmin), Kygo Life and Sinar Baja, the FINE QC system delivers the speed, reliability, and accuracy required for today’s high-volume, high-quality audio manufacturing.

FINE QC Loudspeaker and Audio QC System Applications:

Our FINE QC System will test (Smart) Loudspeaker Systems and drivers, headphones, micro-speakers, microphones, amplifiers and crossovers:

FINE QC Features:

- QC testing Loudspeakers/Drivers, (incl. Bluetooth +Micro), Microphones, Crossovers & Amplifiers.

- Complete QC Test: SPL, Sensitivity, Polarity, Impedance +Rub & Buzz < 1 second.

- Automatic “Golden Average unit” and Automatic saved Statistics.

- Automatic pairing of units, also ideal for finding matching units for headphones.

- FINEBuzz 3.0 (Rub & Buzz) Test, “Best in the Industry” – Just measure some Good and Bad units.

- Average Sensitivity (0.1dB accuracy) and TS parameters.

- Reading Barcode serial number will start test.

- Automatic printing of serial number, Pass/Fail and for example sensitivity.

- All measuring is handled by the hardware giving extremely accurate measurements.

- GRAS and ICP microphones connect directly without extra preamplifiers

- Accurate low Latency Bluetooth measurements due to PC not involved in measurement.

- Directly measures crossover circuits and (Class D) Amplifiers.

- FINE QC Viewer available for checking and making setups for FINE QC.

- Drawings for 3 Test Boxes included.

- New multi-channel 19” USB-2 FINE Hardware 3

- 3 Microphone input channels with selectable 48V Phantom power.

- Main amplifier 25W, balanced.

- XLR balanced Line Out and separate stereo Headphone amplifier.

- Built-in power supply and Power switch on front.

- Same factory calibrated hardware for FINE QC and FINE R+D.

- For windows 7, 8 and 10 (+64bit) with dedicated Windows drivers.

Buy FINE QC - Loudspeaker and Audio QC System now!

FINE QC Learning:

LOUDSOFT Promises:

FINE QC™ Loudspeaker and Audio QC System

End of Line Loudspeaker and Audio QC System

Highly Accurate, Fast and Easy to Use

Buy FINE QC for ONLY 8,500 USD

Frequently Asked Questions about our Loudspeaker and Audio QC Systems:

What is a Loudspeaker and Audio QC System?

A Loudspeaker and Audio QC System is a specialized quality control platform designed to test the acoustic and electrical performance of audio components—such as loudspeakers, headphones, microphones, amplifiers, and crossovers—at the end of a production line. It ensures that only products meeting strict performance standards reach the market.

How does the FINE QC system detect Rub & Buzz issues?

The FINE QC system uses a proprietary, self-learning algorithm called FINEBuzz, the Best in the industry. It analyzes each unit in real-time and identifies Rub & Buzz distortions with extreme precision—replacing the need for subjective human testing.

How fast is the testing process with the FINE QC system?

FINE QC performs full acoustic and impedance testing—including Rub & Buzz detection—in as little as 0.5 to 1 second per unit, enabling true end-of-line testing in high-speed production environments.

Can FINE QC be used with automatic production lines?

Yes. FINE QC includes an Automation Module and TTL I/O interface for seamless integration with automatic or semi-automatic assembly lines. It supports real-time PASS/FAIL outputs and can direct sorting of reject types using an additional USB interface.

Does the system support all audio products?

Absolutely. FINE QC supports testing for a wide range of audio products, including smart speakers, drivers, tweeters, headphones, microspeakers, microphones, amplifiers, and crossovers.

Is specialized training required to operate the system?

No. The system is designed to be intuitive and easy to use. Operators can quickly begin using it without the need for extensive technical training or setup.

Which companies use the FINE QC Loudspeaker and Audio QC System?

Leading audio manufacturers such as Bravox, JL Audio (Garmin), Kygo Life, and Sinar Baja rely on FINE QC to ensure consistent quality in their products.

Can I analyze and store test data for future evaluation?

Yes. FINE QC automatically saves all test data, enabling statistical analysis, traceability, and ongoing performance optimization across production batches.